Key Takeaways

- Not all steel is created equal—selecting the right steel grade and coating is critical for withstanding rural conditions like weather, moisture, and animal impact.

- For rural fencing, galvanized or zinc-coated steel offers the best balance of strength and rust protection.

- Structural applications (barns, sheds, gates) often benefit from mild structural steel, galvanized steel tubing, or weathering steel for low maintenance.

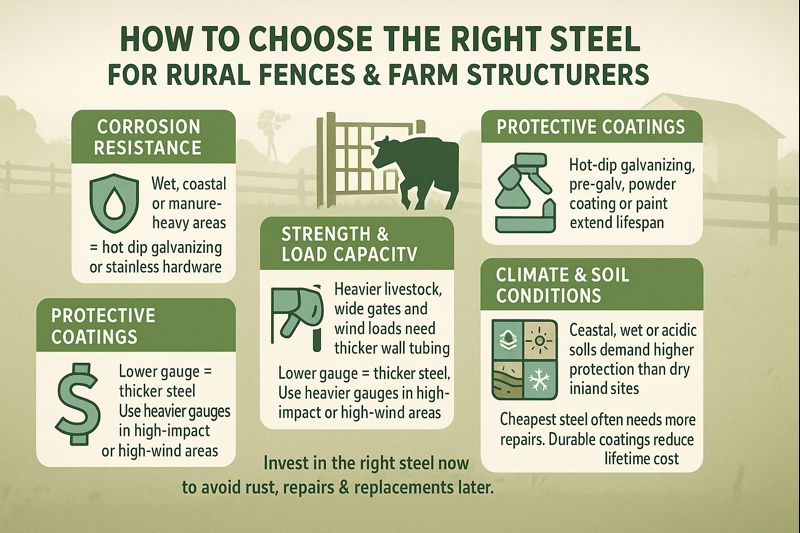

- Consider corrosion resistance, coating type, gauge/thickness, and regional climate when choosing steel for outdoor use.

- Long-term cost savings come from durability and minimal maintenance—not just from the lowest up-front price.

Whether you’re fencing in livestock, building gates, or erecting machinery sheds, the quality of steel you use directly affects longevity, safety, and cost. Rural environments expose steel to wind, water, soil contact, and animal impact — all of which can wear down inferior metals quickly.

This guide will help you choose the best steel types, coatings, and grades for rural applications, including fences, posts, gates, sheds, and barns — while also explaining how to avoid premature rusting, bending, and structural failure.

Choosing the Best Steel for Rural Fencing and Structures

Rural environments are tough on materials. Fences, gates, and outbuildings face constant exposure to weather, livestock pressure, temperature swings, and soil moisture. Selecting the right steel ensures your structures remain strong, safe, and low-maintenance for decades. Understanding the key characteristics of steel for rural use can help you make the best choice for your property.

- Corrosion Resistance

One of the most critical factors in rural steel applications is resistance to rust and corrosion. Steel exposed to rain, UV light, high humidity, and contact with soil or water will naturally deteriorate over time. Using rust-resistant steels, such as galvanized mild steel, stainless steel, or weathering steel, dramatically extends the lifespan of your fences, gates, and structures. Proper corrosion resistance also reduces ongoing repair costs and prevents safety hazards from weakened steel.

- Strength and Load Capacity

Rural structures are not just decorative—they must withstand significant forces. Fences and gates face pressure from livestock pushing against them, high winds, falling branches, and sometimes snow loads. Structures like barns, sheds, or silos need steel that won’t bend or fail under these stresses. Choosing steel with the right yield strength and load-bearing capacity ensures your structures remain stable and functional even under heavy use.

- Weldability and Fabrication

Ease of fabrication is another important consideration. Steel that is easy to cut, weld, and assemble can save significant time and labor during installation. Mild steel is often preferred for rural applications because it is simple to work with on-site and allows for repairs or modifications without specialized equipment. This flexibility is particularly valuable for custom fence designs, gates, or structural modifications that may arise over time.

- Protective Coatings

Even corrosion-resistant steel benefits from an additional layer of protection. Coatings such as zinc galvanizing, powder coating, or patina-forming alloys provide a barrier against moisture and chemicals in the environment. These coatings are especially important in areas prone to wet soil, frequent rainfall, or proximity to livestock, where scratches or abrasions could otherwise expose raw steel to rust. Incorporating protective coatings from the design stage greatly extends the life of your structures.

- Thickness (Gauge)

The thickness of the steel, or its gauge, directly affects its durability. Thicker steel is more resistant to impacts, abrasion, and bending, which is essential in areas with livestock rubbing against fences, machinery contact, or heavy foot traffic. While thicker steel may increase upfront costs, it often pays off in reduced maintenance and longer lifespan.

- Cost vs. Lifespan

While budget is always a consideration, the long-term value of steel should guide your selection. Higher-quality, coated steels may have a higher initial cost but often last two to three times longer than unprotected carbon steel. This reduces ongoing maintenance, repair, and replacement costs, making them a more cost-effective choice over the lifetime of your structures.

Practical Recommendations

- Fences and Gates: Use galvanized or weathering mild steel, with thicker tubing in high-impact areas, especially where livestock pressure is high.

- Rural Buildings and Structures: Choose structural mild steel with protective coatings for sheds, barns, or silos. Consider stainless steel fasteners in damp or corrosive soils to prevent early degradation.

- Maintenance Tips: Inspect fences and structures at least once a year, checking for rust, loose connections, or damage. Touch up coatings or paint as needed to extend lifespan.

Best Steel Types for Rural Fencing

Choosing the right steel for rural fencing and structures is essential for durability, low maintenance, and safety. Different types of steel offer varying benefits depending on environmental exposure, livestock pressure, and design requirements. Below are the most common and effective steel types for rural applications.

1. Hot-Dip Galvanized Steel

What it is:

Mild or carbon steel submerged in molten zinc, creating a metallurgically bonded coating. The zinc acts as a sacrificial barrier, corroding before the steel itself.

Best Uses:

- Fence wire (plain, barbed, hinge-joint)

- T-posts / star pickets

- Gate frames and mesh panels

- Boundary and livestock fencing

- Electric fencing components

Why it’s ideal:

- Affordable & accessible: One of the most common, cost-effective materials for rural fencing.

- Excellent corrosion resistance: Zinc layer protects steel from rain, manure, soil, and UV exposure.

- Long lifespan: Often lasts 15–30 years depending on climate and soil.

- Strong and tough: Suitable for containing cattle, horses, sheep, and property perimeters.

- Low maintenance: No frequent repainting or sealing required.

Extra Advantages:

- Self-healing small scratches via galvanic action.

- Performs well in moderate coastal climates.

- Compatible with common rural hardware like clamps, hinges, and fasteners.

Things to Watch:

- Zinc wears faster in acidic soils, boggy areas, or near groundwater.

- Welded areas lose protective coating—cold-galv or zinc-rich primer recommended.

- Avoid mixing with incompatible metals (e.g., copper) to reduce galvanic corrosion.

2. Galvanized Steel Tubing (RHS/CHS/SHS)

What it is:

Hollow structural steel tubing—Round (CHS), Square (SHS), or Rectangular (RHS)—with internal and external galvanization. Used for posts, frames, and heavier fencing.

Best Uses:

- Farm and driveway gate frames

- H-frames, corner posts, and brace assemblies

- Cattle and horse panels

- Rails, top bars, and heavy enclosures

- Portable or panel fencing systems

Benefits:

- Strong but lightweight: High rigidity with less weight than solid bars.

- Easy to fabricate: Cuts cleanly, welds well, and accepts hinges, caps, or fittings.

- Highly corrosion-resistant: Perfect for rural outdoor conditions.

- Uniform dimensions: Improves consistency for fabrication and DIY assembly.

Additional Advantages:

- RHS/SHS provides excellent bending strength, ideal for long gate frames that resist sagging.

- CHS offers better torsional resistance, great for braces or yard panels.

- Compatible with powder coating for added protection and aesthetics.

Notes to Consider:

- Always treat exposed edges after cutting or drilling with cold-galv spray.

- Use thick-walled options in high-impact livestock environments.

3. Weathering Steel (Corten Steel)

What it is:

Alloy steel containing copper, chromium, and nickel designed to form a stable oxide patina that shields against deeper corrosion.

Best Uses:

- Decorative rural fencing

- Ranch or station signage

- Garden and landscape features

- Architectural accents in rural homes

- Structural elements not in direct soil contact

Why Choose It:

- Very low maintenance: Once the patina forms, no painting or sealing is needed.

- Aesthetic appeal: Natural rust tone suits rustic and modern rural designs.

- Durability: Patina prevents ongoing corrosion, extending steel lifespan.

- Strong structural properties: Often stronger than standard mild steel.

Additional Benefits:

- Blends naturally with timber, stone, and rural landscapes.

- Ideal for premium fencing where appearance is important.

Drawbacks:

- Not suitable for soil contact, pooling water, or constantly damp areas.

- Can stain nearby surfaces during patina formation.

- Higher upfront cost compared to galvanized steel.

4. Black Steel / Mild Steel (Uncoated)

What it is:

Standard carbon steel without protective coating, typically used indoors or in temporary applications.

Best Uses:

- Interior barn frames

- Indoor bracing and partitions

- Painted decorative panels

- Temporary fencing or short-term structures

- DIY projects with a focus on low cost

Advantages:

- Lowest upfront cost: Ideal for budget builds.

- Easy to cut, weld, and fabricate.

- Can be customized with paint, powder coating, or sealants.

Caution:

- Rusts quickly when exposed to weather.

- Requires regular maintenance such as painting or sealing.

- Not suitable for long-term outdoor fencing.

- Moist environments accelerate corrosion significantly.

When It Makes Sense:

- For indoor-only applications

- When budget is tight

- When you plan to apply your own protective coatings

- When longevity is not a priority

Best Steel for Rural Structures: Barns, Sheds, Shelters & More

Rural buildings like barns, sheds, and machinery shelters require steel that can withstand weather exposure, livestock interaction, and heavy loads while remaining low-maintenance and cost-effective. The right steel type depends on the application within the structure—frames, trusses, purlins, doors, or large-span enclosures.

1. Shed & Barn Frames

Recommended Steel: Galvanized mild steel or RHS (Rectangular Hollow Section)

Why it works: These steels are strong, corrosion-resistant, and easy to fabricate. Galvanization protects the steel from rain, moisture, and soil contact, while RHS provides excellent rigidity and dimensional consistency, making frame assembly faster and more reliable.

2. Roof Trusses

Recommended Steel: Pre-galvanized structural steel

Why it works: Lightweight yet durable, pre-galvanized steel is ideal for roof trusses. It reduces the overall weight of the roof structure, making installation easier while still supporting roofing materials. Galvanization adds corrosion resistance, and steel trusses also provide better fire resistance compared to timber.

3. Wall Girts & Purlins

Recommended Steel: C/Z-Purlins (galvanized roll-formed steel)

Why it works: These roll-formed steel profiles offer an excellent strength-to-weight ratio, allowing for large spans without sagging. They are lightweight, durable, and easy to attach to structural frames, making them ideal for walls and roof supports in barns, sheds, and workshops.

4. Barn & Sliding Doors

Recommended Steel: Powder-coated or galvanized steel sheeting

Why it works: Doors are constantly exposed to the elements and frequent use. Powder-coated or galvanized steel sheeting is highly resistant to corrosion, easy to clean, and can withstand repeated handling, livestock impact, and weather exposure without warping or rotting.

5. Machine Shelters & Large Structures

Recommended Steel: Structural steel beams (e.g., ASTM A36)

Why it works: For wide-span structures such as machinery shelters, heavy-duty barns, or multi-purpose sheds, structural steel beams provide the necessary strength and stability. ASTM A36 or similar high-strength steels are robust enough to support large loads, resist bending, and provide long-term durability for industrial and agricultural equipment storage.

Practical Takeaways

- Galvanization or protective coatings are essential for outdoor exposure.

- Hollow sections (RHS/SHS) are ideal for structural frames due to their strength-to-weight ratio and ease of fabrication.

- Roll-formed purlins and girts simplify installation while maintaining large-span support.

- Powder-coated or galvanized sheeting ensures doors and panels remain durable with minimal maintenance.

- Structural beams are necessary for heavy-duty applications and wide spans.

Choosing the right steel for each component of a rural structure maximizes longevity, safety, and efficiency, ensuring barns, sheds, and shelters perform well for decades under challenging rural conditions.

Steel Coatings and Corrosion Protection

Steel used in rural environments is constantly challenged by moisture, manure acids, UV exposure, fluctuating temperatures, and soil chemistry. Choosing the correct coating doesn’t just extend lifespan — it directly affects safety, structural integrity, and long-term costs.

Below are the main coating types, expanded with greater detail and practical recommendations.

1. Hot-Dip Galvanized (HDG)

What It Is:

Steel fully submerged in molten zinc, allowing zinc to metallurgically bond to the surface and form multiple protective layers (zinc-iron alloys + pure zinc topcoat).

Why It Performs So Well:

- Barrier Protection: Zinc physically blocks oxygen, moisture, and salts.

- Sacrificial Protection: Zinc corrodes before steel does, continuing to protect even if scratched.

- Self-Healing: Minor abrasions naturally re-passivate and prevent rust creep.

Best For:

- Posts embedded in soil

- Livestock fencing and heavy-duty farm gates

- Areas exposed to rain, manure, and irrigation

- Yard panels, holding yards, and crush areas

Real-World Lifespan:

20–50+ years depending on:

- Soil pH (acidic soils = faster zinc loss)

- Clay vs. sandy soils

- Rainfall and humidity

- Proximity to coastal salt spray

Additional Advantages:

- Excellent resistance to animal urine (very corrosive).

- Ideal for areas with sprinkler or bore water exposure.

- Works well with powder-coated top layers (duplex protection).

Risks / Things to Watch:

- Zinc consumption accelerates at the soil line (the “critical zone”).

- Welded areas lose zinc entirely unless re-galvanized.

- HDG appearance may dull over time — normal and not a defect.

2. Pre-Galvanized (Zinc-Coated / Z275)

What It Is:

Steel is coated with zinc through a continuous process before shaping. Coating is much thinner and more uniform than HDG.

Coating Thickness:

Around 18–25 µm — roughly ¼ the protection of HDG.

Best For:

- Indoor farm structures (sheds, rafters, purlins)

- Rural buildings with minimal moisture exposure

- Lightweight fence components not contacting soil

Strengths:

- Smooth finish suitable for powder coating

- More economical than hot-dip galvanized

- Good for internal framing and non-critical components

Limitations:

- Not ideal for soil contact

- Cut edges must be sealed, as mill-cut edges have no zinc

- Shorter lifespan outdoors, especially in wet climates

3. Powder-Coated Steel

What It Is:

Dry powdered resin is electrostatically bonded to steel and baked, forming a hard, attractive protective layer.

Best For:

- Gate frames

- Decorative fencing

- Barn doors and shed panels

- High-visibility or aesthetic installations

Why It’s Popular:

- Resists chipping, cracking, and UV fading

- Wide range of colours and textures

- Can be applied over galvanized steel for superior protection (“duplex coating”)

Extra Benefits:

- Prevents chemical attack from fertilizers or manure splash

- Works well on RHS/SHS tubing

- Easy to clean and maintain

Considerations:

- Not a substitute for galvanizing on soil-contact components

- Chips that expose raw steel must be repaired to avoid rust creep

4. Painted Mild Steel

What It Is:

Uncoated carbon steel that is primed and painted to resist corrosion.

Appropriate Uses:

- Indoor barns or workshops

- Short-term fencing solutions

- Non-structural or temporary frames

- Areas with minimal moisture contact

Strengths:

- Very cost-effective

- Easy to repaint or repair

- Suitable for aesthetic, low-impact uses

Limitations:

- Offers the least corrosion resistance overall

- Requires proper surface preparation (cleaning, sanding, degreasing)

- Needs routine repainting, especially outdoors

- Will fail quickly when exposed to soil moisture, manure, or rainfall

Common Mistakes to Avoid

1. Using uncoated mild steel outdoors

It begins to oxidize almost immediately and can lose structural integrity in months, not years.

2. Not sealing welds on galvanized steel

Weld heat removes the zinc, leaving bare steel that becomes a corrosion hotspot.

3. Choosing steel that’s too thin for the job

Thin-walled tubing can:

- Bend under animal impact

- Collapse under wind loading

- Fail at the welds due to thin heat-affected zones

4. Ignoring ground-level corrosion

The soil surface zone is the most aggressive corrosion point:

- High moisture retention

- Oxygen cycling

- Acidic or alkaline soil chemistry

- Manure and urine exposure

5. Using incompatible metals

Mixing steel with uncoated copper, or cheap fasteners, creates galvanic corrosion.

Always match coatings: galvanized-to-galvanized, stainless-to-stainless.

6. Poor drainage and sealed tubing

Trapped water inside tubing causes rapid internal rusting — sometimes unnoticed until failure.

Maintenance Tips for Longevity

✔ Annual Inspection Protocol

Check:

- Welds

- Gate hinge areas

- Soil-level contact points

- Drainage holes in tubing

- Powder-coated surfaces for chips

✔ Cleaning for Corrosion Control

- Remove manure — highly acidic

- Rinse mud and clay buildup (water retention = corrosion)

- Clean salt residues in coastal zones

✔ Touch-Up & Repair Best Practices

- Use zinc-rich cold-galv paint for cut edges and welds

- For powder-coated steel, repair chips immediately to prevent moisture ingress

✔ Painting Recommendations

For mild steel:

- Clean to bare metal

- Apply rust-inhibiting primer

- Finish with 2–3 topcoat layers

✔ Fastener Selection

Use:

- Stainless steel (304 or 316)

- Zinc-coated or hot-dip galvanized screws/bolts

Avoid:

- Black steel screws — they rust first and accelerate corrosion around them.

✔ Drainage & Soil Considerations

- Use post caps on RHS/SHS to prevent water entry

- Drill small drainage holes where needed

- Avoid embedding powder-coated steel directly in soil

- Use gravel or concrete bases to improve drainage

Common Steel Gauges for Rural Projects

Selecting the appropriate steel gauge is essential for durability, safety, and performance in rural fencing, gates, and structures. The gauge determines the thickness of the steel, which directly affects its strength, load-bearing capacity, and resistance to wear, impact, and environmental exposure. Below is a detailed guide on common gauges for various rural applications.

Fence Wire (Barbed or Field Fencing)

Recommended Gauge: 12.5 to 14 gauge

Details: Thicker wire is more resistant to stretching and livestock pressure. For cattle and perimeter fencing, 12.5-gauge wire provides excellent durability and maintains tension over long distances. For sheep or lighter fencing, 14-gauge wire is generally sufficient. High-tensile wire allows for thinner gauges while maintaining superior strength, making it a cost-effective option for large rural properties.

Steel Tubing for Gates

Recommended Gauge: 14 to 16 gauge (approximately 1.6–2.0 mm)

Details: For wide gates exposed to frequent opening and closing, 14-gauge tubing provides the strength needed to prevent sagging and twisting. Smaller paddock gates or decorative gates can use 16-gauge tubing. Rectangular (RHS) and square (SHS) hollow sections typically resist twisting and bending better than round (CHS) tubing, making them preferable for long-term performance.

Purlins & Structural Framing

Recommended Gauge: 12 to 14 gauge

Details: Purlins and roof framing support roofing material and contribute to overall structural stability. Thicker gauges improve strength, particularly in regions with high winds, heavy rainfall, or snow loads. C- and Z-purlins commonly use galvanized steel with thicknesses ranging from 1.8–2.4 mm, balancing rigidity with weight for easier installation.

Sheet Metal Siding & Roofing

Recommended Gauge: 26 to 29 gauge (approximately 0.35–0.55 mm)

Details: 26-gauge steel is recommended for wider spans or high-wind areas where extra rigidity is required. For smaller sheds, barns, or general-purpose roofing, 29-gauge steel is sufficient. Corrugated or ribbed profiles increase structural rigidity, allowing thinner gauges to perform effectively while keeping costs and weight down.

Yard Panels & Cattle Rail

Recommended Gauge: 12 to 13 gauge

Details: Heavy-duty panels and rails must withstand impact from livestock. Thicker wall tubing provides the necessary resistance against repeated contact and forceful pushing. This ensures panels remain upright and safe over time, even in intensive cattle or horse yards.

Gate Braces & H-Frames

Recommended Gauge: 10 to 12 gauge

Details: These critical support structures bear the load of livestock pressure and gate movement. Using thicker wall pipe or RHS ensures braces and H-frames resist bending, twisting, and deformation, providing stability and long-term durability in high-impact areas such as cattle yards or horse arenas.

Practical Takeaways

- Match gauge to application: Thicker steel for high-impact or high-load areas, thinner steel for light-duty or decorative applications.

- Consider livestock type: Cattle require heavier gauges than sheep or smaller animals.

- Factor in environmental exposure: Areas prone to corrosion, wind, or heavy snow benefit from thicker or coated steel.

- Optimize for cost vs. performance: Using unnecessarily thick steel increases cost and weight without proportional benefit; gauge selection should balance durability, function, and budget.

Steel Gauge & Thickness: How Much Is Enough?

Choosing the correct steel gauge (thickness) is essential for achieving the right balance of strength, longevity, and cost-efficiency. Undersized steel can bend, buckle, or corrode prematurely — while oversized material increases project cost without adding meaningful value.

What is “Steel Gauge”?

Steel gauge is a numerical system representing the thickness of sheet metal and tubing.

Lower number = thicker steel.

For example:

- 12-gauge steel ≈ 2.5 mm

- 16-gauge steel ≈ 1.5 mm

Important: Gauge is not universal — sheet steel, tubing, wire, and roofing products may follow different gauge systems. Always verify millimetre thickness when possible.

Key Tip: Strength Starts With Thickness

Always match the gauge to BOTH:

1. Expected Load

- Livestock pressure (cattle vs. sheep vs. horses)

- Machinery contact (tractors, skid loaders)

- Gate span length and hinge load

- Roof snow load / wind uplift

2. Exposure Conditions

- Soil moisture

- Salt corrosion

- UV exposure

- Temperature cycles

For harsh or exposed locations, err toward thicker steel — especially for posts, purlins, and structural frames.

Climate-Specific Steel Recommendations

Rural environments vary widely, and picking the right material based on climate can double or triple your structure’s lifespan.

1. Wet or Coastal Regions

Coastal, high-humid, or high-rainfall areas accelerate rust dramatically.

Best Choices:

- Hot-dip galvanized steel (highest corrosion resistance)

- Aluminium-zinc coated steel (AZ150/AZ200)

- 316 stainless steel for hardware and marine environments

- Thicker-gauge tubing to compensate for long-term corrosion loss

Avoid:

- Bare mild steel

- Pre-galv with thin coatings

- Thin gauge tubing in soil contact

- Unsealed welds (rust appears within months)

Extra Tip:

For posts, use:

- Hot-dip galvanized

- Concrete footings with gravel drainage

- Post caps to prevent internal rusting

Dry Inland Regions

Low rainfall and minimal humidity reduce corrosion risk — but UV exposure and livestock contact remain major factors.

Best Choices:

- Galvanized mild steel (sufficient in most inland areas)

- Powder-coated gates for UV resistance

- 13–16 gauge tubing for general rural fencing

Good to Know:

Dry soils are less corrosive, so lighter gauge steel can still deliver long service life.

2. Cold or Snow-Prone Regions

Snow load, meltwater, and freeze–thaw cycles create unique stressors.

Best Choices:

- Structural steel (12–14 gauge purlins) for roof load

- HDG posts to withstand constant wet/dry cycling

- RHS/SHS framing for superior strength under dynamic load

Avoid:

- Black steel

- Thin-wall tubing exposed to snow

Pre-galv steel in soil contact (coating too thin)

Tip:

Use roof panels with deeper rib profiles to increase snow-shedding and stiffness.

3. High Wind Zones

Wind load affects both fencing and structures.

Best Choices:

- Thicker gauge posts (10–12 gauge)

- Braced gate frames

- Galvanized hinge plates and anchors

- C-purlins / Z-purlins with thicker web thickness

Construction Tips:

- Set fence posts deeper (600–900 mm+ depending on soil)

- Use diagonal bracing on corners and gates

- Anchor shed frames with hot-dip galvanized brackets

Looking to build durable rural fencing or long-lasting farm structures?

Super Steel Australia supplies high-quality galvanized, RHS, C-purlin, and weather-resistant steel products designed specifically for tough rural environments. Whether you’re fencing paddocks, upgrading a barn, or building a new machinery shelter, our team can help you pick the right steel for maximum strength and longevity.

👉 Visit SuperSteel to get expert guidance, fast quotes, and reliable steel delivered right to your property.