Steel sheet is one of the most versatile materials in fabrication. Whether you’re cutting parts for machinery, building brackets and plates, creating architectural features, or fabricating outdoor enclosures, sheet steel gives you a strong, workable base that can be cut, bent, welded, and finished to suit almost any job.

But “steel sheet” isn’t one product. With different grades, coatings, thicknesses, and finishes, choosing the wrong sheet can lead to rust, poor welds, warping, or unnecessary cost.

This guide breaks down the key factors so you can choose the best steel sheet for your project—based on performance, finish quality, and long-term value.

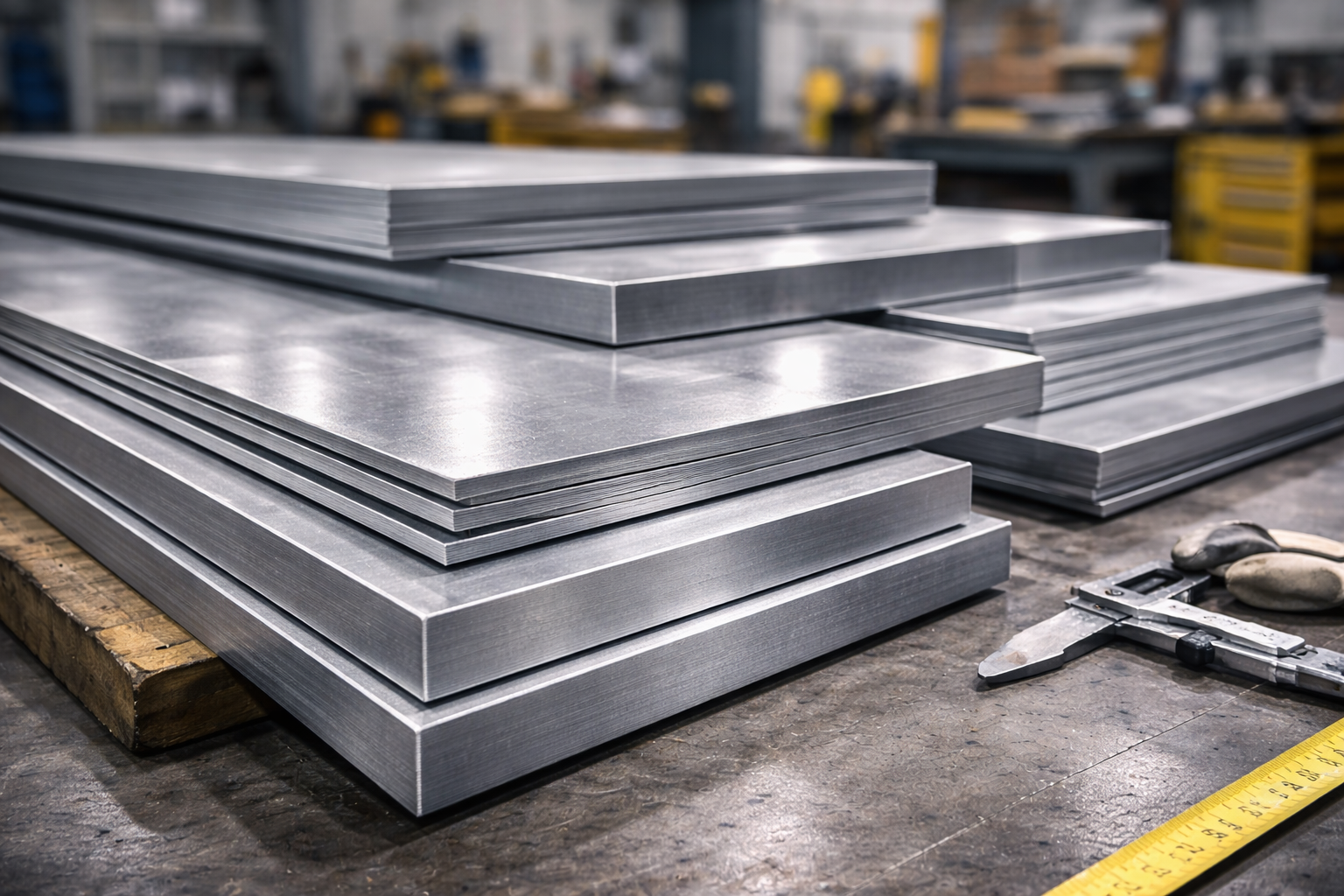

What is Steel Sheet?

Steel sheet is flat-rolled steel supplied in various thicknesses (commonly measured in mm or sometimes gauge) and standard sheet sizes such as 2400 × 1200mm (with custom cut-to-size options available from many suppliers).

Steel sheet is used across:

-

general fabrication (plates, brackets, covers, guards)

-

structural components (gussets, base plates, stiffeners)

-

decorative panels (screens, feature cladding, architectural finishes)

-

cladding and roofing (when using the correct coated products)

-

trailer floors and vehicle parts (checker plate, panels, guards)

-

machinery and enclosure manufacturing (cabinets, housings, shrouds)

Sheets come in both coated and uncoated forms depending on whether they’ll be used indoors or outdoors—and whether corrosion resistance or appearance is the priority.

Key Factors When Choosing Steel Sheet

Choosing steel sheet is really about matching performance + finish + fabrication method to the job. The same sheet that’s perfect for an indoor bracket can be totally wrong for a coastal enclosure or a wear-heavy trailer floor. Use the factors below as your “buying checklist” so you get the right sheet the first time.

1) Material Type / Steel Grade

Your steel grade determines strength, corrosion resistance, weldability, and price. Here’s how to pick quickly:

| Grade | Best Use |

|---|---|

| Mild Steel (250–350 MPa) | Easy to cut/weld; ideal for general fabrication, brackets, frames, plates |

| Stainless Steel (304/316) | High corrosion resistance; food-grade, marine, chemical environments |

| Galvanised Steel | Zinc-coated for rust protection; outdoor and moisture-prone environments |

| Zincalume® / Colorbond® | Roofing/cladding; corrosion resistance + aesthetics (pre-finished options) |

| Hardox / Wear Plate | Abrasion-heavy work; mining, transport, buckets, chutes, liners |

How to choose in plain terms:

-

Need something easy and affordable? → Mild steel

-

Need something that won’t rust easily? → Galvanised or stainless

-

Need something already made for cladding/roofing? → Zincalume/Colorbond-type products

-

Need something that takes constant abrasion/impact? → Wear plate

📌 Tip: For most everyday fabrication (brackets, panels, guards, base plates), mild steel sheet is the best mix of cost and workability.

2) Sheet Thickness

Thickness affects strength, stiffness, dent resistance, cutting effort, and bendability. It’s usually measured in mm (sometimes gauge, where lower gauge = thicker sheet).

| Thickness | Common Use |

|---|---|

| 0.55mm – 1.2mm | Ducting, cladding, signage, light skins and covers |

| 1.6mm – 2.5mm | Brackets, guards, panels, general fabrication |

| 3mm – 6mm | Structural parts, trailer beds, mounting plates, machinery bases |

| 8mm+ | Heavy plate fabrication, high-load parts, wear resistance |

Practical selection tips:

-

If the sheet must stay flat and rigid across a span, go thicker or add folds/ribs.

-

If you need to bend/fold it, make sure your brake press (or hand tools) can handle that thickness.

-

If you’re welding, thicker material generally tolerates heat better with less warping, but it takes more time and prep.

📌 Tip: Thicker sheet = stronger, but harder to cut, heavier to handle, and more difficult to bend. Balance strength with how you’ll fabricate it.

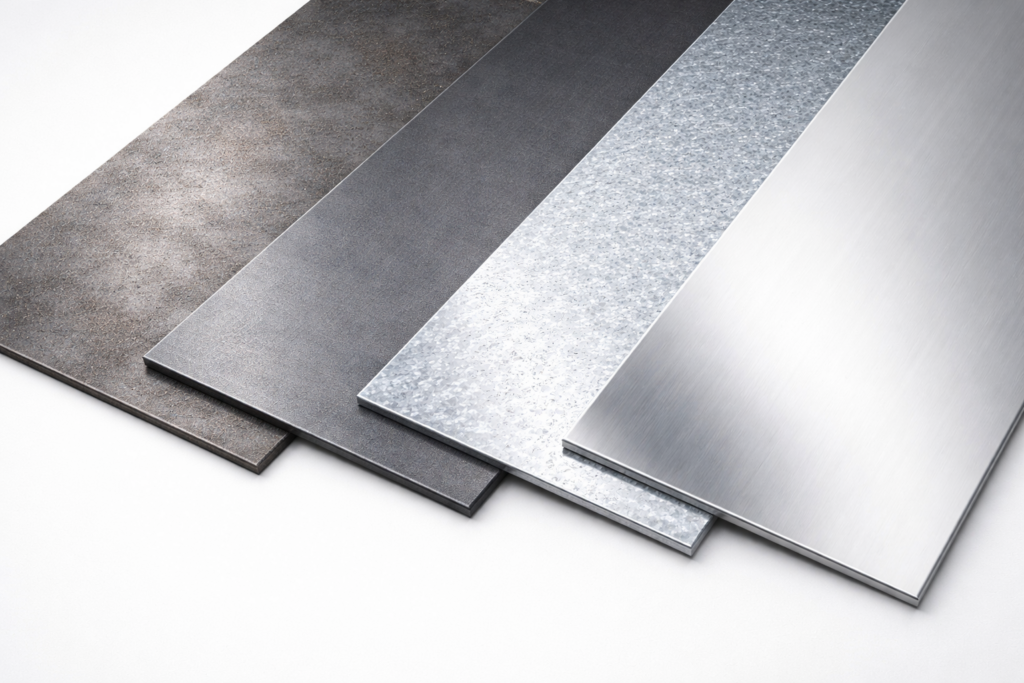

3) Finish or Coating

Finish choice is where most projects either last for years or start rusting early. Pick the finish based on exposure and appearance needs:

| Finish Type | Description | Best For |

|---|---|---|

| Black Steel | Raw/uncoated | Indoor use, or when you’ll prime/paint after fabrication |

| Galvanised | Zinc coating (spangled or smooth) | Outdoor use and corrosion resistance |

| Zincalume® | Zinc/aluminium coating | Roofing, cladding, architectural sheetwork |

| Polished / Brushed Stainless | Decorative, clean finish | Kitchens, marine areas, visible design work |

| Hot Rolled | Slightly rougher finish, lower cost | Structural/hidden components, heavy fabrication |

| Cold Rolled | Smooth + accurate thickness | Precision fabrication, exposed panels, cleaner paint finish |

Rule of thumb:

-

Outdoors + moisture risk → Galvanised/stainless/pre-finished

-

Indoors or fully painted system → Black steel

-

High visual finish required → Cold rolled or stainless

4) Formability vs Strength

This is the trade-off that matters most for fabrication.

If your project involves bending/folding:

-

Choose sheet that forms cleanly and predictably

-

Cold-rolled mild steel is a common go-to for neat bends

-

Galvanised sheet can bend well too, but plan for edge protection and cracking risk depending on thickness and bend radius

If your project is mostly cutting/welding:

-

Mild steel / black steel is usually the easiest and fastest to work with

-

Thicker plate reduces distortion risk, but increases cutting time

If the sheet will see corrosion-prone exposure:

-

Choose galvanised, stainless, or pre-painted options

-

Also plan for edge protection at cut lines, drilled holes, and weld zones (common rust starting points)

5) Weldability & Machining

Different sheets behave differently when you weld, drill, or machine them:

Mild steel

-

Easiest for welding and drilling

-

Wide tolerance for technique and consumables

-

Most forgiving for beginners and general fabrication

Galvanised sheet

-

Requires prep: remove zinc in the weld zone for cleaner welds

-

After welding, re-protect the area (zinc-rich paint/cold galv) to restore corrosion resistance

-

Best practice: good ventilation and PPE during welding

Stainless steel

-

Needs correct consumables and technique

-

More sensitive to heat input (can distort and discolor)

-

Great for corrosion resistance, but typically higher cost and more “process-heavy”

Cutting method selection (quick guide):

-

Thin sheet: guillotine/snips for clean edges, minimal heat

-

Medium plate: plasma is fast; laser for higher precision

-

Thick plate: plasma, oxy cutting, or machining depending on spec

Common Fabrication Uses for Steel Sheet

Steel sheet is one of the most flexible materials in fabrication because you can cut it, fold it, weld it, and finish it to suit almost any job. The key is matching the sheet type and thickness to your project’s load, exposure, and finish requirements.

Here’s a practical guide to common projects and the sheet types that typically work best:

| Project Type | Recommended Sheet |

|---|---|

| Brackets & gussets | 3mm mild steel (easy to weld) or galv if outdoors |

| Trailer sides & floors | 2.5–5mm galvanised for corrosion resistance, or wear plate for abrasion |

| Enclosures & cabinets | 1.6–2mm cold rolled (clean finish) or stainless for corrosive/hygienic areas |

| Roofing & wall cladding | Zincalume® or Colorbond® (made for weather exposure + aesthetics) |

| Custom signs & panels | 1.6mm aluminium (lightweight) or galv sheet (durable outdoors) |

| Skid plates / guards | 4–6mm mild steel (impact resistance) or wear plate for high abrasion |

📌 Quick tip: If it’s going outdoors, think corrosion first—galvanised, stainless, or a proper paint system will dramatically extend lifespan.

Working With Steel Sheets: Pro Tips

Small fabrication habits make a huge difference in how professional your final result looks—and how long it lasts.

✅ Deburr every cut (safety + finish)

After cutting, always deburr the edge. It:

-

removes sharp burrs (safer handling)

-

improves fit-up for welding and assembly

-

helps paint and coatings adhere cleanly

✅ Drill before coating

If you’re drilling mounting holes, do it before painting, powder coating, or galvanising. This avoids:

-

chipping and exposed edges

-

rust starting around freshly drilled holes

-

messy touch-ups later

✅ Outdoor black steel needs the right paint system

If you’re using black (uncoated) steel outdoors, don’t rely on a quick spray coat. For better durability:

-

prep the surface properly

-

use etch primer (or a suitable metal primer)

-

follow with a quality topcoat system

This helps prevent rust creep at edges and weld zones.

✅ PPE matters (sheet work is sharp + dusty)

Steel sheet work involves sharp edges, sparks, and dust—especially when grinding or cutting. Use:

-

gloves

-

eye protection

-

hearing protection when cutting/grinding

-

dust mask/respirator as needed

Final Thoughts

The right steel sheet can make or break your project—affecting cost, finish quality, durability, and ease of fabrication. When you match the sheet to your environment, load requirements, and coating needs, you get cleaner results and fewer long-term problems.

Need Steel Sheet Cut to Size?

Super Steel Australia offers a wide range of steel sheet options, including mild steel, galvanised, stainless, and checker plate—all available cut-to-size, with fast turnaround and expert support for fabricators, trades, and DIYers.

👉 Get in touch with Super Steel Australia today to find the right sheet metal for your project and have it delivered ready to work: https://supersteelaust.com.au/