In construction projects where steel is exposed to the elements, corrosion is one of the biggest long-term threats. Rain, humidity, coastal salt air, irrigation overspray, and even soil contact can cause unprotected steel to rust—leading to weakening, repairs, and early replacement.

Flat bars are used everywhere in construction—from bracing and framing to supports, mounts, and reinforcement plates. But when the job is outdoors (or in harsh industrial environments), Hot Dip Galvanised (HDG) flat bars are the option built for long service life in tough Australian conditions.

If you’re planning an outdoor or high-exposure build, here’s why hot dip flat bars should be high on your materials list.

What Are Hot Dip Galvanised Flat Bars?

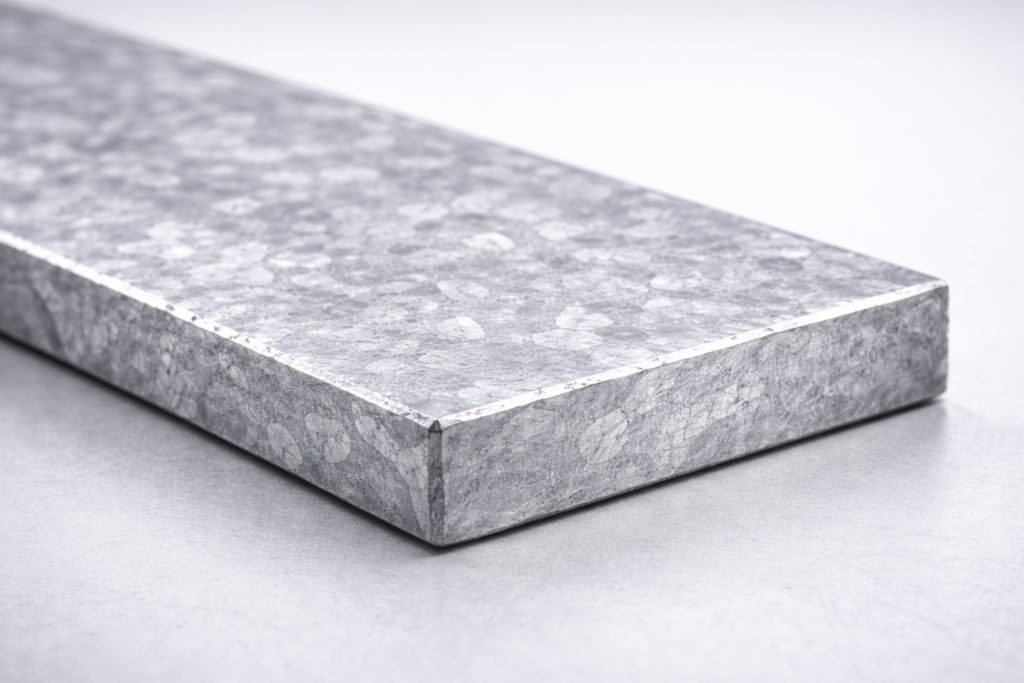

Flat bars are rectangular steel sections with a consistent width and thickness, supplied in straight lengths. They’re a staple in fabrication because they’re simple, strong, and easy to cut, drill, weld, and bolt.

Flat bars are widely used in:

-

framing and bracing

-

supports and tie-down points

-

custom fabrication (tabs, straps, plates, mounts)

-

repairs and reinforcement work

-

brackets and connection plates

What “hot dip galvanised” means

When a flat bar is hot dip galvanised, it’s submerged in molten zinc, which creates a thick protective coating that bonds metallurgically to the steel. This isn’t just a surface paint—hot dip galvanising forms a tough barrier designed to protect steel from corrosion for years.

Key benefits of the HDG coating

✅ Thick zinc protection across the surface

✅ Strong bond to the steel (durable, impact-resistant coating)

✅ Excellent outdoor corrosion resistance

✅ Helps protect cut edges and minor scratches through zinc’s sacrificial action

📌 Why it matters: For exposed steelwork, hot dip galvanised flat bar can dramatically reduce rust risk and maintenance compared to untreated steel.

Why Use HDG Flat Bar? (Benefits + ROI)

Hot Dip Galvanised (HDG) flat bar is one of the smartest choices for outdoor and high-exposure builds because it combines structural reliability with long-term corrosion protection. Instead of relying on paint or post-install maintenance, HDG flat bar is designed to perform in harsh environments from day one.

1) 🛡️ Long-Term Corrosion Protection

HDG flat bar is coated in zinc through a hot dip process, creating a tough barrier against:

-

rain and humidity

-

coastal salt spray

-

irrigation overspray and wet ground

-

industrial pollutants and grime

This helps prevent rust from forming and spreading—especially on exposed edges, brackets, and connection points where corrosion usually starts first.

2) 🔧 Low Maintenance = Less Ongoing Work

Once installed, HDG flat bar typically requires little to no maintenance. Unlike painted steel, the zinc coating won’t peel or flake in the same way, making it ideal for projects that are:

-

difficult to access later

-

built for long service life

-

exposed year-round

✅ Result: fewer touch-ups, fewer rust repairs, and less long-term hassle.

3) 💰 Better ROI Over the Life of the Project

HDG flat bar may cost slightly more upfront than black steel, but it often pays for itself through:

-

reduced need for priming/painting

-

fewer corrosion-related repairs

-

longer replacement cycles

-

less downtime on commercial or rural assets

👉 In short: HDG flat bar lowers your total cost of ownership, especially for medium-to-large builds where maintenance time adds up quickly.

4) 🧱 Tough Coating That Handles Real-World Wear

Construction steel gets dragged, bolted, knocked, and exposed to grit. HDG coatings are designed to handle:

-

abrasion

-

scratches

-

impact during transport and installation

This makes HDG flat bar a safer bet than light coatings in high-use outdoor environments.

5) 🏗️ Reliable Performance for Structural Steelwork

Flat bar is often used in structural support roles (bracing straps, tie plates, mounting points). When those parts rust, the issue isn’t cosmetic—it can become a strength and safety problem.

HDG flat bar helps protect the steel so it stays:

-

stronger for longer

-

easier to inspect

-

less likely to degrade at joints and fixings

📌 Best use case: anywhere steel is exposed and expected to last.

Common Applications for HDG Flat Bar

HDG flat bar is a favourite across construction, fabrication, and rural projects because it’s easy to work with and built for outdoor durability.

🏡 1) Outdoor Fencing and Gates

HDG flat bar is commonly used for:

-

gate bracing straps

-

latch plates and hinge mounts

-

fence brackets and joining plates

-

reinforcement strips to prevent sagging

Because fencing hardware is constantly exposed to weather, HDG protection helps prevent early rust at fixings and weld zones.

🔩 2) Brackets, Tabs, and Mounting Plates

Flat bar is one of the most useful materials for fabrication, especially when you need:

-

mounting tabs

-

connection plates

-

bolt-on brackets

-

support straps and stiffeners

HDG flat bar is ideal here because brackets are often installed outdoors and are hard to repaint once bolted in place.

🌊 3) Coastal and High-Humidity Builds

Coastal air accelerates corrosion fast. HDG flat bar is commonly used in:

-

coastal fencing and handrail systems

-

outdoor frames and supports

-

structural tie-downs and bracing components

-

exposed fixings and reinforcement points

📌 Why it works: zinc coating protects against salt exposure and moisture that would quickly rust untreated steel.

🏗️ 4) Structural Supports and Bracing

HDG flat bar is often used for:

-

cross bracing

-

tie bars and straps

-

reinforcement for frames and posts

-

structural joining plates

It’s a simple but critical component in steelwork—especially where long-term strength matters.

🚜 5) Rural and Agricultural Projects

Farms and rural environments are tough on steel due to:

-

moisture

-

fertilisers and chemicals

-

mud and debris

-

exposure year-round

HDG flat bar is frequently used in:

-

shed bracing and reinforcements

-

livestock yard repairs

-

gate and fence strengthening

-

equipment mounts and supports

🚛 6) Trailers, Utes, and Outdoor Equipment

HDG flat bar is commonly used for:

-

tie-down points

-

reinforcement plates

-

mounting brackets

-

trailer add-ons and repairs

It’s a practical option when you need steel that won’t rust quickly under road spray and outdoor storage.

HDG Flat Bar vs Black Steel Flat Bar vs Pre-Gal Flat Bar (Which One Should You Choose?)

Not all flat bars offer the same corrosion protection. The best option depends on where the steel will be used, how long you need it to last, and whether you’re planning to paint or coat it after fabrication.

Here’s a simple breakdown of the three most common flat bar options:

Quick Comparison Table

| Feature | HDG Flat Bar (Hot Dip Galvanised) | Pre-Gal Flat Bar | Black Steel Flat Bar (Uncoated) |

|---|---|---|---|

| Corrosion Resistance | Excellent | Moderate | Low (will rust outdoors) |

| Best Environment | Outdoor / coastal / high exposure | Low-risk outdoor / sheltered | Indoor / coated after fabrication |

| Coating Type | Thick zinc coating after processing | Lighter zinc coating during production | No coating |

| Maintenance | Very low | Low–moderate | High if left uncoated outdoors |

| Fabrication Ease | Good (prep needed for welding) | Very good | Excellent |

| Cost | Higher upfront | Mid-range | Lowest upfront |

When to Choose HDG Flat Bar (Best for Outdoor Longevity)

Choose Hot Dip Galvanised flat bar when your project is exposed to:

-

rain, humidity, and constant weathering

-

coastal air and salt spray

-

ground contact or damp environments

-

rural/agricultural conditions

-

industrial exposure and grime

HDG is the best choice when you want:

-

maximum rust protection

-

minimal maintenance

-

long service life

-

stronger long-term value for outdoor builds

📌 Best for: fencing hardware, coastal projects, structural bracing, exposed brackets, outdoor frameworks, and long-life steelwork.

When to Choose Pre-Gal Flat Bar (Good for Light Exposure + Clean Fabrication)

Pre-gal flat bar is often chosen when you want some corrosion resistance but don’t need the heavy-duty performance of HDG.

It’s a good option for:

-

sheltered outdoor projects

-

light-duty fencing and brackets

-

indoor/outdoor crossover builds

-

jobs where cost is important but you still want a zinc-coated surface

📌 Best for: general fabrication where exposure is moderate and long-term corrosion demand is lower.

When to Choose Black Steel Flat Bar (Best for Indoor + Painted Builds)

Black steel flat bar is raw, uncoated steel. It’s ideal when:

-

the steel will be used indoors

-

you’re fabricating and painting/priming afterward

-

you want the easiest cutting and welding process

-

corrosion isn’t a major concern (or you’ll fully protect it later)

📌 Best for: indoor brackets, workshop frames, machinery mounts, and projects with a full paint system applied after fabrication.

⚠️ Important: If black steel is used outdoors without protection, it will rust quickly—especially at cut edges and weld zones.

Verdict: Which Flat Bar is Best?

If your flat bar will be outdoors and you want it to last:

✅ HDG flat bar is the best all-round option for corrosion resistance, long-term durability, and low maintenance.

If your build is sheltered and you want a lighter zinc coating:

✅ Pre-gal flat bar is a solid mid-range option.

If your project is indoor or you’re painting everything:

✅ Black steel flat bar is the most cost-effective and easiest to fabricate.

Available Sizes and Standards

Hot dip galvanised flat bars are available in a broad range of sizes to suit everything from light brackets to heavy structural support and bracing.

Common size ranges

-

Widths: typically 10mm–300mm

-

Thicknesses: typically 3mm–25mm

-

Lengths: commonly supplied in 6m lengths (with cut-to-size options available)

That size variety makes HDG flat bar useful for:

-

bracing straps and tie plates

-

mounting plates and brackets

-

reinforcement and repairs

-

structural connections where corrosion resistance is needed

Australian standards (what they mean in practice)

HDG flat bars are commonly supplied to standards such as:

-

AS/NZS 3679.1 – Structural Steel

This relates to structural-grade steel material requirements for bars and sections—important when the flat bar is being used in load-bearing or structural applications. -

AS/NZS 4680 – Hot Dip Galvanising Standard

This specifies requirements for hot dip galvanised coatings applied after fabrication—helpful when corrosion protection and coating quality matter for outdoor steelwork.

📌 Tip: If you’re using flat bar in a structural role, always confirm the grade, standard compliance, and coating specification with your supplier—especially for engineered builds.

Working With Hot Dip Flat Bars: Best Practices

HDG flat bar is built for durability, but how you cut, weld, store, and install it makes a big difference to long-term corrosion performance.

Use proper PPE when cutting or welding

Cutting and grinding HDG steel creates sparks and debris, and welding galvanised steel requires correct safety precautions. Always use:

-

gloves

-

eye protection

-

hearing protection (grinders/saws)

-

respiratory protection as appropriate

-

good ventilation, especially for welding

Prep weld zones properly (then restore protection)

If you’re welding HDG flat bar:

-

grind back the zinc coating around the weld area for a clean, consistent weld

-

weld using appropriate technique and ventilation

-

treat the weld zone after fabrication with cold galvanising spray or a zinc-rich repair system to restore corrosion protection

📌 Why this matters: Weld zones and heat-affected areas are where rust most commonly starts if the zinc protection isn’t restored.

Drill or punch holes before galvanising (if possible)

If you’re fabricating parts that will be galvanised after:

-

drill/punch mounting holes first

-

complete fabrication before galvanising

-

avoid drilling after galvanising unless necessary (exposed edges need protection)

📌 Practical benefit: Pre-drilled holes reduce touch-up work and help keep corrosion protection consistent—especially around fasteners and mounting points.

Store flat bars correctly to prevent “white rust”

“White rust” is a white, chalky zinc oxidation that can form when freshly galvanised steel is stored in damp conditions without airflow.

To prevent it:

-

store flat bars off the ground

-

keep them covered but ventilated

-

avoid trapping moisture between stacked pieces

-

install promptly if possible

📌 Tip: HDG steel should be stored dry with airflow—moisture + tight stacking is what causes white rust.

Final Thoughts

When you need reliable, low-maintenance steel that performs in tough conditions, Hot Dip Galvanised Flat Bars are the perfect solution. They combine the strength of steel with the long-term protection of zinc, making them a top choice for modern construction projects across Australia.

Need High-Quality Hot Dip Flat Bars?

Super Steel Australia supplies a wide range of hot dip galvanised flat bars in various sizes and thicknesses — ready for immediate dispatch or cut-to-length. Trusted by builders, contractors, and councils alike, we deliver steel that lasts.

👉 Contact Super Steel Australia today to get the right flat bar for your project — with corrosion resistance built in.