When you’re building anything exposed to weather—whether it’s a fence, pergola, retaining wall, carport, trailer frame, or industrial steelwork—corrosion resistance isn’t optional. Rust can weaken steel fast, especially in coastal air, high humidity, rainfall zones, or harsh industrial environments.

That’s why Hot Dip Galvanised (HDG) steel is one of the most trusted choices for outdoor projects. It delivers long-term protection, reduces maintenance, and helps steel structures stay strong for years—even in tough conditions.

In this guide, we’ll explain what hot dip galvanising is, how it works, and why it’s a smart investment for outdoor steel builds.

What is Hot Dip Galvanised Steel?

Hot Dip Galvanising is a corrosion-protection process where steel is immersed in molten zinc, forming a tough protective coating that helps prevent rust.

Unlike paint (which sits on top of the metal), the zinc coating in HDG steel metallurgically bonds with the steel surface. That creates a durable, multi-layer barrier designed to withstand outdoor exposure and protect the steel underneath.

Key properties of HDG steel

✅ Fully coated inside and out

Hot dip galvanising coats the entire steel surface—including edges, corners, and hard-to-reach areas—helping reduce weak spots where rust usually starts.

✅ Long-lasting corrosion protection

The zinc coating acts as a barrier against moisture, oxygen, and contaminants, significantly slowing corrosion.

✅ Scratch and abrasion resistance

HDG coatings are thicker and tougher than many standard coatings, making them more resistant to handling damage and site wear.

✅ Self-healing for small scratches or chips

If the coating is lightly scratched, zinc can still protect nearby exposed steel through sacrificial action, helping slow corrosion at minor damage points.

📌 Why it matters: For outdoor builds, HDG steel can mean years of durability with far less maintenance compared to untreated steel.

Why Choose Hot Dip Galvanised Steel for Outdoor Use?

If your steel project will be exposed to rain, humidity, salt air, mud, irrigation, or harsh weather, corrosion protection isn’t optional — it’s essential. Outdoor steel that isn’t properly protected will eventually rust, weaken, and require repairs or replacement.

That’s why Hot Dip Galvanised (HDG) steel is one of the most trusted materials for outdoor construction. The zinc coating forms a tough protective barrier that helps steel resist rust in conditions where painted or untreated steel often fails.

Below are the biggest reasons HDG steel is a smart choice for outdoor builds.

1) 🛡️ Exceptional Corrosion Resistance (Built for Harsh Conditions)

Hot dip galvanising protects steel with a thick zinc coating that shields it from the main causes of rust: moisture, oxygen, salt, and pollutants.

HDG steel is especially effective in environments where corrosion is accelerated, such as:

-

Rain and high humidity

Constant moisture exposure can cause bare steel to rust quickly, especially in shaded or poorly ventilated areas where steel stays damp longer. -

Coastal salt spray and sea air

Salt is extremely corrosive. It attracts moisture and creates an aggressive environment where untreated steel can degrade fast. -

Acidic soil or ground contact

Steel installed near soil, mulch, garden beds, or damp ground is exposed to moisture and minerals that speed up corrosion. -

Pollutants and chemical exposure

Industrial areas, workshops, farms, and high-traffic environments can expose steel to contaminants that wear down coatings over time.

Unlike paint, the zinc coating doesn’t just sit on top — it becomes a durable protective layer that helps shield the steel underneath.

📌 Real-world performance: Hot dip galvanising can offer 20–50+ years of corrosion protection depending on coating thickness, exposure, and environment — making it one of the longest-lasting anti-rust solutions available for outdoor steel.

2) 🔧 Maintenance-Free Durability (No Ongoing Coating Hassles)

One of the most appealing benefits of HDG steel is how little maintenance it needs after installation.

Once HDG steel is installed, it typically requires:

-

no repainting

-

no resealing

-

no re-coating

-

no annual rust treatments

-

no constant inspection for peeling paint

That’s a major advantage compared to painted steel, where moisture can creep under the coating and cause corrosion to spread unseen. With HDG steel, the zinc coating is designed to last and protect the steel long-term without needing constant upkeep.

✅ Why this matters: If your steel is hard to access (like roof structures, under-deck supports, or long fence runs), HDG saves you years of maintenance headaches.

3) 💰 Cost-Effective Over Time (Lower Lifetime Ownership Cost)

HDG steel may have a slightly higher upfront cost than untreated or lightly coated steel — but it usually saves money in the long run because it reduces:

-

maintenance labour and materials

-

repainting costs

-

corrosion repairs

-

premature replacement

-

downtime for commercial/industrial assets

This is especially important for medium-to-large outdoor builds like:

-

fencing and gates

-

pergolas and carports

-

structural frames

-

retaining wall posts

-

rural sheds and farm infrastructure

👉 Bottom line: HDG steel is often the more economical option over the life of a project because it stays functional longer and requires far less ongoing attention.

4) 🧱 Tough and Impact Resistant (Made for Real-World Handling)

Outdoor steel doesn’t live in perfect conditions. It gets bumped, dragged, hit with tools, scratched during transport, and exposed to grit, mud, and debris.

Hot dip galvanising creates a strong alloy layer that’s designed to handle real-world abuse, making HDG steel highly resistant to:

-

scratches and surface wear

-

abrasion from dirt and debris

-

handling damage during transport

-

chips and knocks during installation

Painted steel can chip easily and expose bare metal underneath, which becomes a rust starting point. HDG steel is tougher by design — making it a better option for projects where the steel will be exposed and used hard.

📌 Where this matters most: fencing, rural builds, trailer frames, structural posts, industrial frames, and outdoor supports.

5) ♻️ Environmentally Friendly (Sustainable and Recyclable)

HDG steel isn’t just durable — it can also be a more sustainable choice over the long term.

Why?

-

Steel is 100% recyclable without losing structural strength

-

Zinc is a natural material and is also recyclable

-

Long lifespan reduces the need for replacement materials

-

Minimal maintenance means fewer repainting cycles and less coating waste over time

In other words, HDG steel supports sustainable construction because it lasts longer, needs fewer repairs, and reduces ongoing resource use.

Quick Summary: When HDG Steel is the Best Choice

Hot dip galvanised steel is ideal if your project is:

✅ Outdoors year-round

✅ In a coastal or high-humidity area

✅ Exposed to rain, irrigation, or wet ground

✅ Used in a rural or industrial environment

✅ Difficult to repaint or maintain later

✅ Built for long-term durability and low upkeep

Best Applications for Hot Dip Galvanised Steel

Hot Dip Galvanised (HDG) steel is one of the best choices for projects exposed to weather, moisture, salt air, and ground contact. Because the zinc coating fully protects the steel (including edges and hard-to-reach areas), HDG is ideal for builds where rust prevention and long service life matter most.

Here are some of the most common and best-fit applications:

| Application | Why HDG is Ideal |

|---|---|

| Outdoor fencing and gates | Long-term weather resistance with minimal maintenance |

| Pergolas and shade structures | Durable protection against rain, humidity, and UV exposure |

| Retaining wall supports | Excellent corrosion protection in soil-contact or damp zones |

| Coastal or marine builds | Zinc coating helps resist salt corrosion and harsh exposure |

| Rural & agricultural projects | Handles moisture, fertiliser exposure, and tough outdoor conditions |

| Outdoor staircases and balconies | Helps safety-critical components stay structurally sound and rust-free |

📌 Why HDG stands out here: These projects are typically exposed year-round and often difficult (or expensive) to repaint or maintain later—so long-term corrosion protection is the smart option.

HDG Steel vs Other Coatings (What Lasts Longest Outdoors?)

Not all “galvanised” or coated steel offers the same level of protection. The biggest differences come down to how the coating is applied, how well it covers the steel, and how thick the protective layer is.

Coating Comparison Table

| Feature | Hot Dip Galvanised | Pre-Galvanised | Powder Coated |

|---|---|---|---|

| Coating Process | Immersed in molten zinc | Zinc coated before fabrication | Electrostatic powder then baked |

| Coverage | Full, even (including inside tubes) | Mainly surface-level protection | Surface only |

| Typical Thickness | 50–100+ microns | 10–20 microns | Variable (40–120 microns) |

| Best For | Harsh outdoor conditions | Indoor or low-risk outdoor | Decorative indoor/outdoor use |

What this means in real-world builds

Hot Dip Galvanised steel is generally the best option when:

-

the steel will be outdoors permanently

-

it’s exposed to moisture, salt, or soil contact

-

you want the lowest maintenance over the longest lifespan

-

the steel is structural or safety-critical

Pre-galvanised steel is a good choice for:

-

light outdoor exposure

-

sheltered structures

-

projects where cost and fabrication speed matter more than maximum coating thickness

Powder coating is ideal when:

-

appearance is a priority

-

the steel is visible (architectural builds, screens, rails)

-

you want colour + UV resistance

-

the steel is not in constant wet or abrasive conditions

📌 Verdict: HDG steel is superior for structural integrity, harsh outdoor exposure, and long service life, especially where rust could compromise safety or performance.

Things to Keep in Mind (HDG Steel Practical Notes)

HDG steel is extremely durable, but there are a few important installation and fabrication considerations to keep your build strong and corrosion-resistant long term.

✅ Weld Prep and protection

If welding HDG steel:

-

grind off the zinc coating in the weld zone before welding

-

weld with correct ventilation and safety practices

-

treat weld zones afterward using cold galvanising spray or an approved zinc repair system to restore protection

📌 Why it matters: Weld zones are one of the most common places rust starts if they’re left unprotected.

✅ Coating thickness and weight

HDG adds a small amount of thickness and weight. It’s not usually a major issue, but it’s worth considering when:

-

fitting tight tolerances

-

sliding sections into sleeves

-

planning engineered load calculations

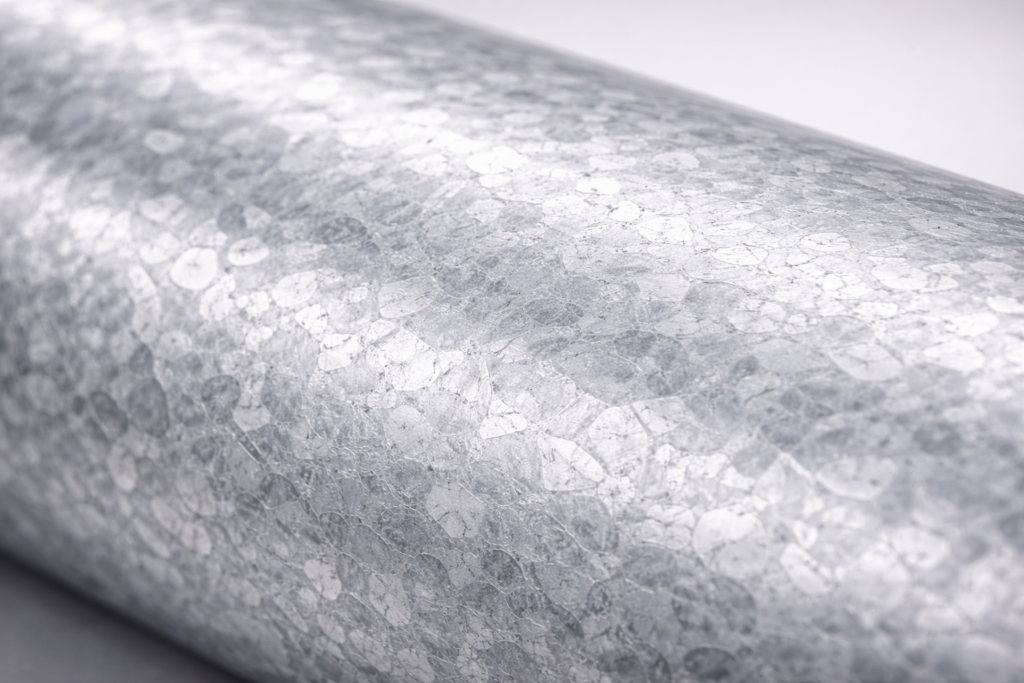

✅ Appearance over time

HDG steel typically has a matte silver finish (often with a “spangled” look). Over time it may dull slightly, but it remains protective.

📌 Important: The finish changing slightly doesn’t mean it’s failing—it’s part of how zinc naturally weathers while still protecting the steel underneath.

Final Thoughts

If your project needs strength, rust resistance, and minimal maintenance, Hot Dip Galvanised Steel is one of the best long-term solutions available. From DIY builds to commercial infrastructure, HDG is trusted because it holds up in the toughest environments—rain, humidity, salt air, soil contact, and heavy outdoor wear.

Need High-Quality Hot Dip Galvanised Steel?

Super Steel Australia supplies a wide range of hot dip galvanised steel, including RHS, SHS, flat bars, angles, and custom structural profiles—all compliant with Australian standards and ready for outdoor use.

👉 Contact Super Steel Australia today for expert advice, quotes, and fast delivery: https://supersteelaust.com.au/